WE CAN MAXIMIZE YOUR PROFIT

Metal Cutting

SolutionsCUTTING TOOL

- End Mills

- Indexable Inserts

- Taps

- Reamers & Drills

- Center Drills- Cutter

- Hobs & Broaches

- Special Tools

- Regrinding Tool Services

- Saw Blade & Saw MachineTOOL HOLDERS & WORK HOLDERS

- Collet Chuck Arbors

- Shrink-fit Holders,

- Hydraulic Tool Holders- High-Speed Spindle Machines,

- Clamping

- Tool PresetterIndustrial Quality

SolutionsSurface Finishing

SolutionsAbrasive & Polishing Tools

- Sandbelts

- Polishing Stone

- Ceramic Brushes&Stones

- Mounted Point Tools- Hand Grinders

- Polishing Compounds

- Barrel Machine

- Abrasive MediaGrinding Tools

- Grinding Wheels,

- Grinding Stones

- CBN and Diamond Wheels for Regrinding ToolsSmart Manufacturing

SolutionsTest &

Measurement

More

CategoryMetalworking Fluid

Pollution Control And Maintenance

Metal Cutting

SolutionsCUTTING TOOL

- End Mills

- Indexable Inserts

- Taps

- Reamers & Drills

- Center Drills- Cutter

- Hobs & Broaches

- Special Tools

- Regrinding Tool Services

- Saw Blade & Saw MachineTOOL HOLDERS & WORK HOLDERS

- Collet Chuck Arbors

- Shrink-fit Holders,

- Hydraulic Tool Holders- High-Speed Spindle Machines,

- Clamping

- Tool PresetterIndustrial Quality

SolutionsSurface Finishing

SolutionsAbrasive & Polishing Tools

- Sandbelts

- Polishing Stone

- Ceramic Brushes&Stones

- Mounted Point Tools- Hand Grinders

- Polishing Compounds

- Barrel Machine

- Abrasive MediaGrinding Tools

- Grinding Wheels,

- Grinding Stones

- CBN and Diamond Wheels for Regrinding ToolsSmart Manufacturing

SolutionsTest &

Measurement

More

CategoryMetalworking Fluid

Pollution Control And Maintenance

Home » Surface Finishing Solutions » TIPTON

The

Mass Finishing

Company

Tipton dreams of a quality future environment

by technological progress.

Products

Finishing Machine・Peripheral Equipment

Leading Market Share in Japan A Comprehensive Manufacturer in the Mass Finishing Industry

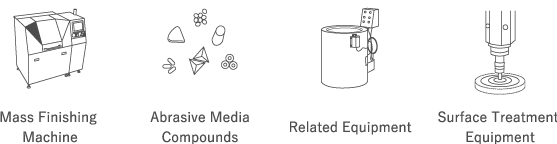

The Complete Lineup of Mass Finishing Products

Because we are the leading manufacturer of a complete line-up of mass finishing products, we have the technical advantage to provide products to a diverse range of corporate customers that includes the major car manufacturers and electric and electronic manufacturers.

A Substantial Line-up of Basic Rotary Models Through to the Very Latest Hi-gravitational Models and Periphery Equipments

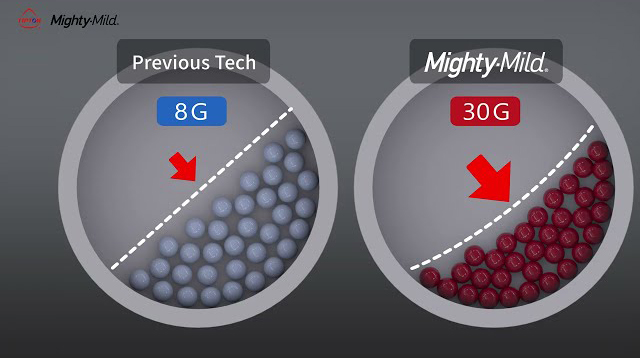

We sell a substantial line-up of products — from basic rotary barrel finishing machines through to the very latest hi-gravitational barrel finishing machines, separators, driers and other periphery equipments in and outside Japan. Technical invention that has obtained many patents that are the foundation of product development continually improves the precision of our finishing machines. For example, the latest model of the Mighty-Mild barrel finishing machine features improved performance and an enhanced design, and is contributing to the growth of the mass finishing industry.

Supporting Custom Layouts, Automation and the Design and Production of Brushing, Lapping and other Special-purpose Machines

We can offer our customers the benefits of comprehensive system design as we handle not only finishing machine units but also related equipment, surface treatment equipment and other special-purpose machines. In particular, we have an established track record in the area of layout machines for mass finishing machines and automatic machines. We have a substantial testing environment at our headquarters that allow testing from large 1,000 mm sizes down to small products of less than 1 mm. In this way, we can provide highly reliable designs.

Responding to All Kinds of Requests with Over 2,000 Types of Abrasive Media and Compounds

Through original development of over 2,000 types of abrasive consumables, we are able to design finishing machines capable of satisfying a diverse range of finishing requirements. As a leading manufacturer in the mass finishing industry, our technical strengths support the business operations of a variety of corporations. We can also develop abrasive consumables matched to specific customer requirements. For details, see [Abrasive Media and Compounds]